- Posted by Lance on February 21, 2003 at 11:34:16

In Reply to: Re: 47'ing the Class A Joplin - Final Results posted by Derick on February 21, 2003 at 04:21:34:

I spent the early part of my engineering career working on very high power (>100 KW) short wave transmitters. At that time (the 1960's), silicon rectifier stacks were just starting to be used to replace the mercury vapor rectifiers that were then in use. I can remember pulling out hundreds of 870B water cooled MV rectifiers (20KV@ 20A, 2000A filament) and replacing them with silicon. I also worked on many smaller transmitters that used 857B, 575A, 872, 866, 816, etc. MV rectifiers. The engineering community breathed a collective sigh of relief when these things went away. They are accidents waiting to happen and the standing joke at the time was not if you were going to have a problem with a MV rectifier but when.I know they look nice, have low volatge drop and impedance but the negatives are serious. Here are a few:

1) MV rectifiers that are new or have been laid on their side for some reason need to have their filaments run for 20-30 minutes without HV applied to make sure that the mercury is vaporized and out of the filament and other tube electrodes where it can cause internal shorts.

2) Under voltage on the filament (like only 10%) can cause immediate tube failure because of inadequate mercury vaporisation.

3) All MV rectifiers need to have their filaments warmed up for 45-60 seconds before HV is applied to assure that the mercury is vaporized. Failure to ensure adequate warm up time can cause back bombardment of the filament and destroy the oxide coating in a matter of minutes. This means you will need a separate filament supply with a switch or time-delay relay.

4) Mercury vapor rectifiers are prone to "arc-over" or "flash-over" caused by under or over vaporization problems and just random weirdness. If you have never seen an MV rectifier flash over just wait, if you are using them, and eventually it will happen. Tube implosions are very rare (caused by disentegrating and flying pieces of tube elements) but that was one of the reasons MV rectifiers were frequently in cages. Most big transmitters always had a spare rectifier that could be switched in when one of the MV tubes arced-over. It will scare the pants off you when it happens.

5) MV rectifiers, because of the gas plasma, can generate huge amounts of broadband noise that need to be filtered out by special "hash chokes" in the anode leads and by invasive bypassing. This doesn't always happen but it does occur frequently. This was another reason that they were in shielded cages.

6) MV rectifiers are temperature sensitive and need to be operated over a realtively narrow range.

I know an 83 is a long way from an 870B but it still is subject to the same problems on a smaller scale. I have seen some new audio amplifiers using 866A rectifiers and there is no legitimate reason to use them. If you must use a gas rectifier use a 3B28 instead. This xenon-filled equivalent of the 866 was invented just to circumvent all the problems with MV tube.

Don't use MV....they are one family of tubes that deserve to be forgotten.

Follow Ups:

- Re: MV Rectifiers - OK-OK-OK! - Lance 20:57:51 02/21/03

(6)

- In Reply to: MV Rectifiers - Ugh! posted by Lance on February 21, 2003 at 11:34:16:

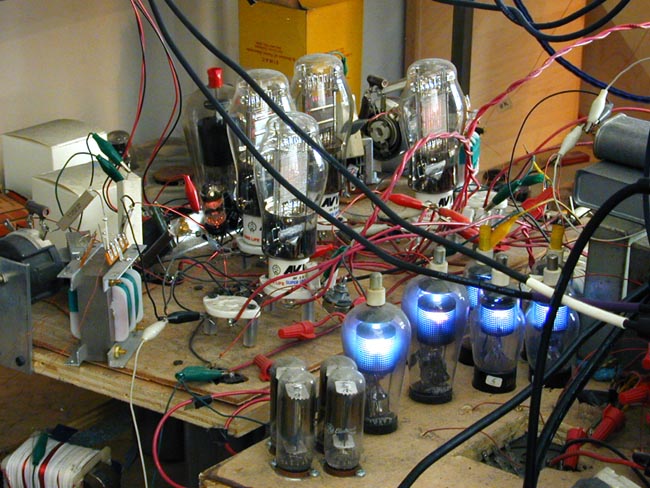

I understand everyone's point. I am just relaying my experience with literally thousands of MV tubes that I have worked with in my career. In the photo I see what I think is an 83 mounted horizontally (please correct me if I am wrong). This is an accident waiting to happen. No MV rectifier should ever be operated in this position. When you have one flash-over on you for the first time I am sure that you will think differently.

- Re: MV Rectifiers - OK-OK-OK! - Ivan303 21:38:21 02/21/03

(5)

- In Reply to: Re: MV Rectifiers - OK-OK-OK! posted by Lance on February 21, 2003 at 20:57:51:

In the picture I posted, the 83 is the rear tube, the 2A3 is in the middle and the 801A is in front. All are upright. The two 816's are on either side, also upright..

- Re: MV Rectifiers - OK-OK-OK! - Lance 22:16:01 02/21/03

(4)

- In Reply to: Re: MV Rectifiers - OK-OK-OK! posted by Ivan303 on February 21, 2003 at 21:38:21:

OK, I was reading the posts on my crummy little laptop and couldn't see the image well. I transferred over to the desktop and I can see the 83 plainly to the right (rear). Again, I'm not trying to be irritating. I just have seen so many bad experiences with these tubes in commercial operation.

- Re: MV Rectifiers - OK-OK-OK! - Dave-A 16:33:50 02/23/03

(3)

- In Reply to: Re: MV Rectifiers - OK-OK-OK! posted by Lance on February 21, 2003 at 22:16:01:

I wonder if using these big industrial rectifiers in a much lower power application makes them better [and safer] to use.

I have experienced something like flashover when I powered up the amps too quickly, but I simply turned off the B+ and let the filimants heat up a little more. I have had no problems since. It seems like 30 sec. will take care of that.

- Seriously consider the 3B28 - Lance 17:50:30 02/23/03

(1)

- In Reply to: Re: MV Rectifiers - OK-OK-OK! posted by Dave-A on February 23, 2003 at 16:33:50:

I know that many DIY amp builders like MV rectifiers. Please consider using the 3B28 in place of the 816 or 866. This tube has all of the benefits of MV but with much greater safety and less hassle. This tube was developed SPECIFICALLY to overcome many of the MV problems. The 3B28 is filled with Xenon gas. The problem with MV is the transition state between the liquid state of condensed Hg and the formation of Hg vapor. Most of the problems are related to maintaining the correct vapor concentration since the natural state of Hg is a liquid. This is not a problem with Xenon since its natural state is a gas.

The 3B28 still needs adequate warm-up time for its filament but it is much shorter, normally on the order of 15 sec. There is another similar rectifier called the 3B25 but it is a little harder to find.

I would also look at the 836. This is a high vaccum rectifier and thus will have greater voltage drop but it has twin cathodes (the tube is half-wave)so voltage drop is at a minimum and internal impedance is very low. This may also be a possible replacement.

- Re: Seriously consider the 3B28 - Dave-A 06:30:02 02/24/03

(0)

- In Reply to: Seriously consider the 3B28 posted by Lance on February 23, 2003 at 17:50:30:

Thanks Lance. I will look into these.

- Re: Seriously consider the 3B28 - Dave-A 06:30:02 02/24/03

(0)

- More MV rectifier info. - Lance 17:18:11 02/23/03

(0)

- In Reply to: Re: MV Rectifiers - OK-OK-OK! posted by Dave-A on February 23, 2003 at 16:33:50:

What you saw was not a flash-over. A flash-over occurs with HV applied and is essentially an internal short. What you saw was an effect caused by insufficiently developed gas plasma caused by not allowing the tube to heat up long enough. Formation of the gas plasma is important as it protects the filament from back bombardment from high-velocity positive ions. This back bombardment will eventually destroy the oxide coating on the filament. These tubes are also sensitive to over and under filament voltage. In commercial use most are operated with some type of a constant-volatge transformer that incorporates both over and under voltage relays which will open the HV supply primary if an out of range filament voltage is detected.

Undoubtedly, running MVR at lower ratings will help but all the issues with filament voltage,warmup and temperature range are still present.

One last thing. MV rectifiers can have breakdown efects in the MV plasma if subjected to strong magnetic fields. They should be located a reasonable distance from chokes, power tansformers and OPT's. If subjected continually to these fields tube life will be shortened.

Check the particular tube specs. for the recommended warm-up time.

- Seriously consider the 3B28 - Lance 17:50:30 02/23/03

(1)

- Re: MV Rectifiers - OK-OK-OK! - Dave-A 16:33:50 02/23/03

(3)

- Re: MV Rectifiers - OK-OK-OK! - Lance 22:16:01 02/21/03

(4)

- Re: MV Rectifiers - OK-OK-OK! - Ivan303 21:38:21 02/21/03

(5)

- MV Rectifiers - Mmmmmm Good! - Ivan303 17:59:18 02/21/03

(1)

- In Reply to: MV Rectifiers - Ugh! posted by Lance on February 21, 2003 at 11:34:16:

All very good points that should be kept in mind when working with MV rectifiers.

My experience with the reliability of MV rectifiers is a bit different than yours. Most of my experience is in using them WAY below their ratings limit. We should be careful of that kind of thinking or we might all be back listening to Sand Amps, before we know it:-)

I have a good friend who is in his mid 80's and still at his bench every day including Saturdays. He uses an old High Voltage Power Supply on his bench and claims he has had the same 866's running in it for about 40 years. Uses it every day.

Quite a number of tube testers use the 83 without problems.

I have a collection of 816's and 866's; both US types and the slim Amperex 866AX's. Also have a few of the ST shaped 866 Taylor JR's. Would love to get my hands on a few Taylor Globes and especially the Taylor Globe JR's, as they have no top cap, the only real legitimate risk I can think of, especially to pets and children.

I understand that physical placement can be a bit of an issue as it relates to other components in the system. Note the location of the 816's in Terry Cain's great sounding 2A3 amps pictured above. Also note the 83 located out of the way in the rear. Yep, a separate power supply for the 801A driver!

As for the Mercury itself, not near the problem as the organic form that we are adding to our food chain daily from mining and chemical processing. Millions of tons a year from the US alone.

"If it measures good and sounds bad, -- it is bad. If it sounds good and measures bad, -- you've measured the wrong thing."

Daniel R. von Recklinghausen

- Re: MV Thyratrons - Derick 18:14:06 02/21/03

(0)

- In Reply to: MV Rectifiers - Mmmmmm Good! posted by Ivan303 on February 21, 2003 at 17:59:18:

More:

- Re: MV Thyratrons - Derick 18:14:06 02/21/03

(0)

- Re: MV Rectifiers - Ugh! - tomt 17:23:03 02/21/03

(0)

- In Reply to: MV Rectifiers - Ugh! posted by Lance on February 21, 2003 at 11:34:16:

i will not give up or 'for get' mv tubes

- Re: MV Rectifiers - Ugh! - Derick 13:39:26 02/21/03

(5)

- In Reply to: MV Rectifiers - Ugh! posted by Lance on February 21, 2003 at 11:34:16:

> > > Don't use MV....they are one family of tubes that deserve to be forgotten. < < <

----There are some who haven't forgotten them =^) Check out the link way below (article on Josh Stippich). It may be overkill or "wrong" but I'm not qualified to judge or challenge that. He is inspired by Sakuma and other Japanese tube circuit designers who abandoned conventions or regressed further back to 30's technology. BTW, Josh custom builds amps (his website www.electronluv.com is currently down, in there you will find his Eimac 75TL monoblocks 8W per channel with a lot of amorphous C-core chokes from Tribute) I take all of this with a grain of salt of course, it's all a matter of taste. And I know that MV's are a pain in the ass to use and implement, and as you cited the only real reason that some diy'rs like 'em is their low internal impedance that gives heftier bass compared to other rectifiers and of course the cool glow (I know it's kinda vain, but what you posted about 47's it made me imagine of a 83-47-300Bamp glowing in a dimly lit room) BTW, I think the commercial amps you saw with 866's are the ones from Legend Audio.

Anyway, I'm not about to do such project since I do not have the technical capability or even the budget to start one that complex (for me at least).

Here are some other links with MV rectifiers in amps:

www.vt52.com

http://www.audiodesignguide.com/se/katelelo.html

Some good read from Lynn Olson's site especially about the very early WE amps (no relation to MV rectifiers here, just some interesting stuff to read):http://www.aloha-audio.com/library/index.html

- Gassy Tubes - Lance 21:08:10 02/21/03

(2)

- In Reply to: Re: MV Rectifiers - Ugh! posted by Derick on February 21, 2003 at 13:39:26:

I worked at Eimac between 1974-79 and I know their tubes quite well. One thing that concerns me; however, is that tubes such as the 75TL/H, 304TL/H, etc. are designed to operate at realatively high voltages (2000-3000 VDC). At 8 watts out I am sure that Josh is running them at lower voltages. I see in the photo that tubes are showing no "color". These tubes have no getter in them and impurities and small amounts of gas are "gettered" by the tube running at a minimum of a visually red hot plate and preferably a bright orange. The tubes are desihned to run this way. If run at lower plate voltages this gettering process does not occur and eventually the tube will go gassy.

- Re: Gassy Tubes - Ivan303 21:45:11 02/21/03

(1)

- In Reply to: Gassy Tubes posted by Lance on February 21, 2003 at 21:08:10:

Good that you make that point.

I will see Josh on Saturday and be sure to pass that along.

Would a 10 - 15 min. blast of voltage/current every week or so do the job?

This is one outstanding sounding amp, now that he has the new Tribute Amorphos C core IT, Anode Chokes, and Parafeed OT in place.

- Re: Gassy Tubes - Lance 22:11:02 02/21/03

(0)

- In Reply to: Re: Gassy Tubes posted by Ivan303 on February 21, 2003 at 21:45:11:

I don't want to blow things out of proportion on this but it is something to consider long term. I remember having a conversation on this subject with Bill Eitel and Bob Sutherland of Eimac. I would not know how to relate a "therapeutic gettering" of one of these tubes to time of operation. These tubes have a very hard vacuuum and are very sensitive to impurities and residual gas. In all probability, he will have no problem. I would prefer to see a gassy tube now and then then to have the tube run a 3KV. These types of tubes were never designed for consumer equipment and the voltages are just too dangerous. I am certain he knows all this if he is making the amps commercially. Bill and Bob are both gone now but I do know one ex-Eimac old timer who is still around. I'll call him and review the subject again.

- Re: Gassy Tubes - Lance 22:11:02 02/21/03

(0)

- Re: Gassy Tubes - Ivan303 21:45:11 02/21/03

(1)

- Re: MV Rectifiers - Ugh! - Derick 14:11:54 02/21/03

(1)

- In Reply to: Re: MV Rectifiers - Ugh! posted by Derick on February 21, 2003 at 13:39:26:

I prefer thinner ala Mapleshade speaker cables though than the ones used here.

- MV Rectifiers - Mmmmmm Good! - Ivan303 17:22:11 02/21/03

(0)

- In Reply to: Re: MV Rectifiers - Ugh! posted by Derick on February 21, 2003 at 14:11:54:

Those amps would sound GREAT with my custon white lamp cord as speaker wire:-)

- MV Rectifiers - Mmmmmm Good! - Ivan303 17:22:11 02/21/03

(0)

- Gassy Tubes - Lance 21:08:10 02/21/03

(2)

This post is made possible by the generous support of people like you and our sponsors:

You can not post to an archived thread.