Slate TT Project

98.167.237.235 |

||

| Posted on November 29, 2011 at 15:44:13 | ||

|

Posts: 41

Location: Mesa,AZ Joined: August 30, 2005 |

I acquired a TT of my dreams,a Denon DP-80.Now all I had to do was manufacture a plinth that would do this TT justice,and make it sing. So after considerable research,and corresponding with a number of plinth builders and material suppliers,this is my TT and it does indeed sing!I have never heard a TT that has such powerful bass,and yet articulates the mids and highs with such liquidity Three layers of Baltic Birch topped with a 3/4" piece of slate,and 4 slate feet with 1/4" inserts to attach the footers.The rubber mat has been replaced with a Specialty designed Delrin mat and a soilid silver phono cable from Applied Fidelity,who also replaced and upgraded all of the caps as a precautionary measure,to prevent the danger of failure,as they are over 30 years old. |

|

| RE: Slate TT Project, posted on November 29, 2011 at 15:50:07 | |

|

Posts: 7738

Location: Powell, Wyoming Joined: July 23, 2007 |

Oh yeah... it's a beautiful thing! Very impressive. |

| Sssssssmokin'! nt, posted on November 29, 2011 at 16:10:24 | |

| nt | |

| That's a Beauty Alright!, posted on November 29, 2011 at 16:28:52 | |

|

Posts: 189

Joined: November 26, 2011 |

Nice Job! |

| Tomahawk arm wand?, posted on November 29, 2011 at 16:48:38 | |

| I'm still using the carbon fiber wand. | |

| stunning., posted on November 30, 2011 at 00:26:18 | |

|

Posts: 4699

Joined: April 12, 2002 |

That's a fantastic job. enjoy, mark |

| RE: Couple questions..., posted on November 30, 2011 at 07:38:00 | |

|

Posts: 41

Location: Mesa,AZ Joined: August 30, 2005 |

The footers are model V2D-SS and are made by Simplyphsics |

| Sexy !, posted on November 30, 2011 at 15:28:36 | |

|

Posts: 553

Location: Cambridge Joined: March 2, 2010 |

I love the design of that Denon table. And slate is beautiful. Keep clear of oil ! rr |

| RE: Sexy !, posted on November 30, 2011 at 15:56:54 | |

|

Posts: 599

Location: North East Joined: November 13, 2010 |

What kind of LT tone arm is that?Beautiful TT! |

| RE: Sexy !, posted on November 30, 2011 at 16:07:36 | |

|

Posts: 41

Location: Mesa,AZ Joined: August 30, 2005 |

Terminator Pro |

| RE: Jim, Have you accessed the bearing?, posted on November 30, 2011 at 18:57:25 | |

|

Posts: 415

Joined: March 20, 2008 |

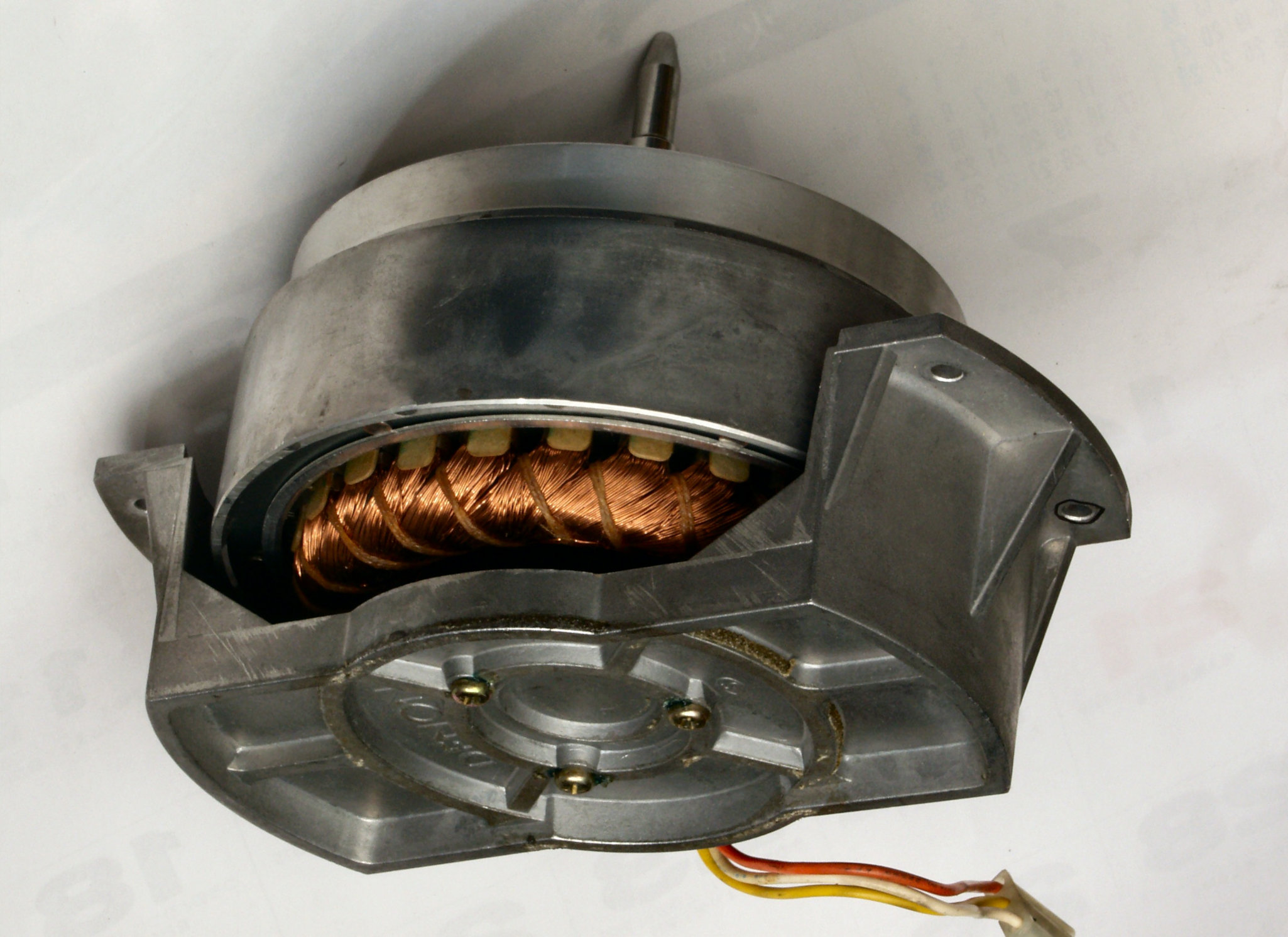

Lew: "Despite my best search efforts, I have never been able to find any useful information about the DP80 bearing..." Some pictures of the bearing in the DP-80 from the Japanese website amp8.com with many hi-rez pictures. Unfortunately, they didn't post a picture of the bearing. I remember the induction motors in models like DP3000 uses good bearings so the one in the DP80 should be just as good or better. http://www.amp8.com/amp-etc/record/denon/dp-80.htm http://www.amp8.com/amp-etc/record/denon/dp-80-3.htm  |

| The pic..., posted on November 30, 2011 at 19:49:12 | |

|

Posts: 10505

Location: Great Basin Joined: May 7, 2005 |

At last... "Help support our school's Music programs" |

| RE: I like that...., posted on December 1, 2011 at 03:20:43 | |

|

Posts: 3

Location: Burb of Chicago Joined: September 2, 2005 |

Beautiful! PLEASE throw in a pic of the Green Mountains! |

| RE: I like that...., posted on December 1, 2011 at 09:55:04 | |

|

Posts: 41

Location: Mesa,AZ Joined: August 30, 2005 |

Here is the entire system! |

| That reminds me of a couple of Denon plinths..., posted on December 1, 2011 at 11:47:18 | |

|

Posts: 6828

Location: Glen Burnie, MD USA Joined: December 18, 2003 |

But I'm sure your's is probably much more dense with the use of the baltic birch under the slate. You should have contacted Oswald's Mills Audio for the slate. They do beautiful slate work using a Pennsylvania blue hue slate that is finished using some high tech machinery of some nature. Its not cheap but those plinths are certainly beautiful. IIRC Denon made a couple of series of tables based on the DP-1000 and DP-2000 motors. The tables were named something like the DP-1750 and/or DP-1780 (or substitute the 2xxx for the 1xxx for the 2000 series motor unit in the Denon plinth). I'm pretty sure that that the 1750 came with a marble top and the other model came with a slate or lead top on the wooden plinth. I like the look of your table a lot and I'm sure she sings nicely. Nice work, Ed Life is analog...digital is just samples thereof |

| So much for my memory..., posted on December 1, 2011 at 12:06:15 | |

|

Posts: 6828

Location: Glen Burnie, MD USA Joined: December 18, 2003 |

One of them was the DP-1800: One was the DP-2800:  The DP-3000 in the same marble topped plinth:  I'm still trying to locate the lead/slate top plinth Denon that I saw somewhere... Ed Life is analog...digital is just samples thereof |

| Thanks Lew. This must be the theory that Rega uses with their rigid tonearms?, posted on December 2, 2011 at 00:21:02 | |

|

Posts: 7738

Joined: December 9, 2000 Contributor Since: November 1, 2005 |

nt |