|

|

||

|

FAQ Search Asylum Trader |

|

|

|

||

|

FAQ Search Asylum Trader |

|

Touring the Plant by Rod M

On August 10th, 2003, probably the hottest day of the Summer with temperatures peaking at 116 degrees in the inland areas of California, I made the trek up to Manley Laboratories headquarters and factory in beautiful Chino, California, just a stones throw from Chino Hilton, AKA California Institute for Men, the home of 6,298 of California's finest. Thankfully, EveAnna Manley's facilities are well insulated and air conditioned with nary a convict in sight!Needless to say, I was impressed. Manley Labs is no garage operation. The facility is 11,000 square feet and they are capably of making just about anything from circuit boards to transformers. I suspect that if EveAnna had the time, she'd even start up tube production!

After a tastefully late arrival, EveAnna met me in the lobby. As usual for those that know her, she was impeccably dressed, fresh from the salon and outfitted in fine dancing shoes. I, on the other hand, felt like a slob having come so casually attired.

Manley Labs - In the parts racks with finished case

Deep in the bowels of the factory is a warden of inventory shelving housing all of the raw parts. EveAnna poses here with a Snapper chassis, which, incidently was also silk-screened here as well. Within these cavernous racks lie literally hundreds of thousands of dollars in parts. Boxes and boxes, filled to the brim with exotic capacitors and the like, resistors, transformers, you name it, it's here.

Manley Machine Shop

Manley Labs machines many of their metal parts in their own machine shop. Pictured here are two of the four Bridgeport mills. They also have a great old Cadillac lathe and a Time Saver line graining machine. They polish and line grain all the parts in house because they know how picky hifi customers can be about fit 'n' finish.

Manley Labs - Boards

Shown here are some printed circuit boards ready for mechanical assembly

Manley Labs - Mechanical Assembly

Here is Saulo bolting in the printed circuit board into a Snapper chassis. Saulo has worked with EveAnna since 1989. The nail polish you see on his bench are not to beautify his nails. Saulo dabs a dollop of nail polish on all the screws and nuts as an anti-vibration measure so they don't wiggle loose during transport

Manley Labs - Board Stuffing

Manley's PCB's are stuffed by hand by a lovely team of girls upstairs. Most of the boards are also hand soldered by these ladies, although once every ten days they fire up the wave solder machine to run some of the boards through there. Tube sockets for instance are not very wave machine friendly so that's why the majority of the Manley boards are still done by hand.

Downstairs, Manley also boosts a complete board fabrication facility. Prototypes can be designed one day and be fabbed and ready for stuffing the next.

Manley Labs - Tube Test Jig

As Manley is only as good as their worst tube, each tube goes through a battery of pre-qualification before it is allowed in the Quality Control room or into any amplifiers. Seen here are two burn-in jigs for 9-pin miniature tubes and a purpose-built noise testing rig they designed and built to grade tube noise and microphonics. Downstairs are some more dedicated jigs for batching output tubes and selecting for good triode-to-triode matching for dual triodes used in differential circuits.

If you need to match a tube in any Manley gear that happens to die, just call the factory and you'll be asked for the number written on the tube. Presto, an instant match is off to you in the mail.

Manley Labs - EveAnna over looking transformer winding

EveAnna Manley, sporting her new long sleeved Manley Biker SWAG, looks on as Tim winds some little chokes used in their Pultec Equalizers. Manley's in-house transformer winding facility winds all of their audio transformers and chokes. Only the power transformers are sourced out.

Manley Labs - Tube Recording Microphone

About 85% of Manley's business is in the professional recording industry. Here is the guts of the Manley Gold Mic. The capsules are made by David Josephson in Northern California while all the guts, casing, pcb, and output transformer are made in Chino, CA at the Manley factory. Absolutely no Chinese parts in this mic!

Manley Labs - Now what? More wiring?

A stack of Steelheads piles up on Toto's bench waiting for him to complete all the hand-wiring. See those huge 30uF MultiCap® bombs in there?

Manley Labs - Wiring and more wiring...

Estella will take this bundle of wires in the Snapper and create a finished work of art which will be as beautiful as she is.

Manley Labs - QC, hmmm why doesn't this one work?

Aptly named, HUMberto helps Neil figure out a trouble at also aptly named, SMOKEY's test bench. Seven QC Testers test, align, calibrate, burn-in and re-calibrate output from the whole factory before shipping.

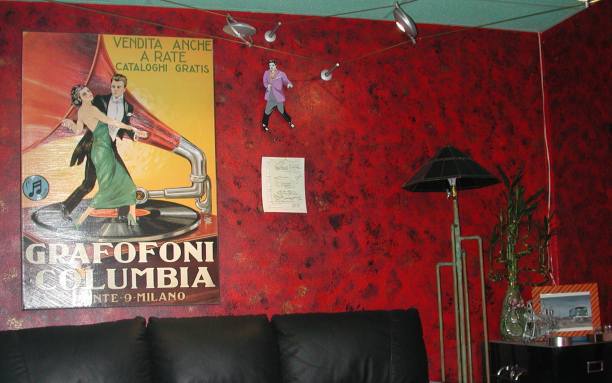

Manley Labs - EveAnna's office complete with dancing Elvis clock

CEO EveAnna Manley cannot be accused of having a boring office. Original SKIPJACK design conceptual drawing is tacked up under the dancing Elvis clock. Flying Saucer halogen lights sourced from IKEA. Lucky Bamboo in corner given to her by her tenants next door who import the stuff.

Each and every office was equally unique, sporting creative paint jobs and decorations. One featured 45 RPM records on the walls and hanging from the ceiling. And of course, every company should have a PacMan video game in the lobby!